The Hualian double folding industrial heat sealing machine delivers clean, secure sealing for 20–25 kg paper-plastic bags. With double-folded edges and easy-tear hot-melt strips, it offers fast unpacking and a premium, professional finish.

Hualian’s double folding and heat sealing machine is designed for 20–25 kg paper-plastic composite bags, creating clean double-folded edges and applying customizable hot-melt easy-tear strips. It makes unpacking effortless while delivering neat, premium-looking packaging.

• Doppelklapp- und Versiegelungsmaschine der FBC -Serie

| √ | Hohe Effizienz | √ | Hoher Ausgang |

| √ | Kleiner Fußabdruck | √ | Multifunktion |

| √ | Gutes Versiegelungsaussehen |

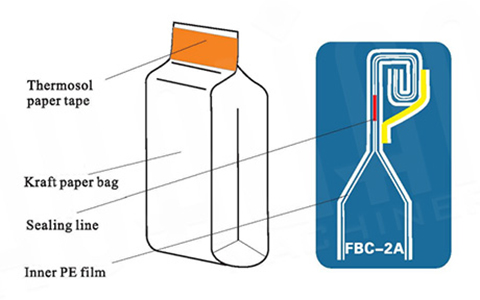

• Art der Taschenverpackung

• Versiegelungssequenz

Dedusting-Inner-Bag-Versiegelungsinner-Tasche, die das Trimmen beeindrucken

| Gute Versiegelungsleistung

This double folding automatic heat sealer adopts a controllable constant-heating device to press and seal the inner plastic layer, ensuring excellent sealing performance. It delivers dust-proof, moisture-proof, and contamination-resistant packaging that effectively protects your products. |  |

| Automatisierter Betrieb

As a highly efficient double folding automatic bag sealing machine, it completes the entire packaging workflow automatically through a PLC-controlled program. The process includes dedusting, inner bag sealing, folding, tape application, and final sealing—ensuring a smooth, consistent, and fully automated packaging cycle. |

| Anpassbarkeit

This double folding industrial heat sealing machine can be equipped with an optional dedusting system to clean the bag opening. It supports various bag formats, including monolayer bags, multilayer bags, kraft paper bags, and paper-plastic composite bags, offering strong adaptability for different packaging requirements.

|  |

| Vielseitige Integration

Kann leicht in eine komplette Produktionslinie mit zusätzlichen Geräten wie automatischem Wiegen, Füllung, Palletisierung, Schnall- und Filmverpackung integriert werden und die allgemeine Produktionseffizienz verbessert. |

| Bequemlichkeit der Reparatur von Nachverkäufen

Hervorragender Kauf ohne Sorge nach dem Verkauf | |

|  |  |

| Chemische Industrie | Verbindungsdüngerindustrie | Technische Kunststoffindustrie |

|  |  |

| Futterindustrie | Lebensmittelzusatzindustrie | Medizinisches Zwischenprodukt |

| Modell | FBC-2 | FBC-2D |

| Spannung (V/Hz) | AC 380/50 | |

| Bruttokraft (kw) | 5.5 | 6 |

| Übertragungsleistung (kw) | 0.75 | |

| Heizkraft (kW) | 4.5 | |

| Deduster Power (KW) | – | 0.6 |

| Versiegelungsgeschwindigkeit (m/min) | 0-11 | |

| Höhe vom Dichtungszentrum bis zum Boden (mm) | 750-1450 | |

| Temperaturbereich (℃) | 0-400 | |

| Luftquellendruck (MPA) | 0.6 | |

| Deduster | × | √ |

| Spezifikation von heißem Schmelveband (MM) | Breite 70 mm , Papierkerndurchmesser 75 mm | |

| Externe Dimension (L × W × H) (mm) | 3550 × 950 × 1800 | |

| Nettogewicht (kg) | 350 | |

Yes. It can connect with weighing, filling, palletizing, strapping, and film-wrapping equipment.

Yes. An optional dedusting mechanism is available to clean the bag opening before sealing.

It uses a constant-temperature heating device that pinches the inner plastic layer to create a tight, durable seal.

A one-year warranty, one-to-one technical guidance, and remote troubleshooting are included.

The FBK-23C bag sealing machine is a high-performance bag packaging solution designed for heavy-duty applications. It is specifically engineered for 25–50kg heavy bags, making it an ideal industrial bag sealer for demanding production environments.

This heavy duty sealer supports a wide range of bag types, including single or multi-layer paper bags, paper-PE composite bags, 2-in-1 and 3-in-1 bags, aluminum-PE liner bags, and PE bags—ensuring maximum flexibility for industrial packaging needs.