Hualian непрерывный лоток вакуумной упаковки машина применима для герметизации видов PP или PE лоток, может закончить процесс вакуумирования, газовой промывки, герметизации и резки пленки и так далее.Широко используется в готовой пищи, ланч-бокс, готовые блюда, и т.д.Он может продлить срок службы продуктов, сохраняя продукт, чтобы быть свежим и предотвращения продуктов.

• Столовая лоток с кожей HVT Series Machine

| √ | Высокая эффективность | √ | Умный контроль |

| √ | Компактный дизайн | √ | Гибкие формы |

| √ | Мониторинг в реальном времени |

КАРТА |  Вакуумная упаковка |  Только герметизация |  Упаковка кожи (необязательно) |

| Высокоэффективная упаковка лотка

Достичь до 5-6 пакетов карт за мин с вакуумным насосом 360/V |  |

| Долговечная свежесть

Используйте метод замены газа, который сводит к минимуму потребление газа, одновременно сохраняя свежесть пищи в течение более длительного периода, продлевая срок годности и уменьшая отходы.

|

| Eazy и безопасная операция

Легкое обслуживание: Оснащенный специальными треками, после разблокировки плесени, ее можно напрямую вытащить для легкой разборки и технического обслуживания. |  |

| В режиме реального времени: Может быть измерено с помощью цифрового датчика давления и наблюдения за изменениями давления в форме

Ошибка в реальном времени функция быстрого времени : Установленный с помощью аварийного переключателя, если есть какая -либо исключительная ситуация, клиент может нажать этот переключатель, чтобы остановить всю программу работает, чтобы обеспечить безопасность машины и людей. |

| Одна машина для нескольких целей

Принятые замеными формами для обновлений продукта клиента можно использовать одну наборную машину |  |

| Высококачественное строительство

Пищевые материалы: Основные компоненты изготовлены из нержавеющей стали или алюминиевого сплава, который соответствует стандартам гигиены пищевых продуктов и гарантирует, что процесс упаковки является безопасным и надежным.

Компактная структура: Он экономит пространство пола, легко эксплуатироваться и подходит для различных рабочих сред. |

| Удобство послепродажного ремонта Отличная послепродажная покупка без беспокойства гарантия составляет один год. Профессиональная послепродажная пропродажна Один-один предоставляет услуги удаленной помощи | |

|  |  |

| Курица | Фрукты | Морепродукты |

|  |  |

| Мясо | Креветка | Овощ |

| Модель | HVT-350AZ |

| Напряжение (V/Гц) | 3PH AC 380/50 |

| Власть (кВт) | 9 кВт |

| Коэффициент замены газа | Более 99,5% |

| Макс. Высота стандартной машины (мм) | 80 мм |

| Размер подноса (мм) (L*W) | Max.280*170 (4 лотка/цикл) мин.180*100 (6 подносов/цикл) |

| Емкость | 4-5 (упаковка карты, с вакуумным насосом 360 м3/ч) (циклы/мин) |

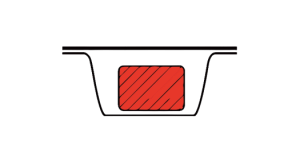

A лоток герметик is a packaging device that seals plastic film onto trays of various materials.sizes, and depths. lt is widely used to preserve the freshness and extend the shelf life offood products.

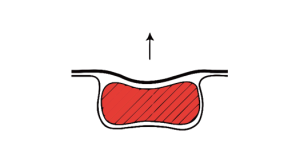

After the tray is filled with products, it enters the sealer manually or via a conveyor belt.After the tray is positioned, the sealing plate descends, pressing the film to the tray,sealing the film to the tray by heating, and cutting the excess film at the same time.

Только уплотнение, вакуумное уплотнение, карта, кожный пакет.

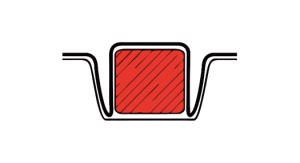

Карта-это технология, которая может сохранить мясо, фрукты и овощи на основе низкотемпературного хранения путем искусственного изменения компонентов окружающих газов

Packaging boxes: PP, PE, PET, etc.Heat-sealing films: PET/CPP, PET/PE, OPP/CPP, EVOH, aluminum foil and composite filmthat can be heat-sealed with corresponding packaging boxes.

Когда selecting a tray sealer, factors such as product type, production requirements, traysize and material should be considered to ensure the equipment meets the specificapplication needs.

Regularly clean and inspect key components such as heating elements and sealing moldsto ensure proper operation and extended life of the equipment.

The production speed depends on the specific model and application. We have manuato automatic models, and different models have different speeds.

Hualian map tray sealing machine is applicable to sealing various PP or PE trays and, as a reliable map tray sealer machine, can automatically complete vacuuming, gas flushing, sealing and film cutting. It effectively prolongs product shelf life while keeping the contents fresh and protected.