Машина для запечатывания лотков Hualian, применяется для автоматического запечатывания пленкой лотка из материала PP, PE. Вакуумный газопромывочный упакованный лоток (высота продуктов не должна превышать высоту лотка) может продлить время жизни продуктов, сохраняя их свежесть и предотвращая их от влаги и плесени, как разнообразные лотки для свежих продуктов, лотки для фаст-фуда и ланч-боксы для студентов в супермаркетах.

Hualian непрерывное уплотнение лотка, применима к автоматическому сбрасыванию пленки лотка, изготовленного из PP, материала PE. Вакуумный упакованный газовый поднос (высота продуктов не должна превышать высоту подноса) может продлить время для продуктов, сохраняя при этом продукт свежим и предотвращая продукты от влаги и плесени, например, разнообразие подноса свежих продуктов, лоток и ланч-ланш-лан студентов быстрого питания в супермаркетах.

Hualian непрерывное уплотнение лотка, применима к автоматическому сбрасыванию пленки лотка, изготовленного из PP, материала PE. Вакуумный упакованный газовый поднос (высота продуктов не должна превышать высоту подноса) может продлить время для продуктов, сохраняя при этом продукт свежим и предотвращая продукты от влаги и плесени, например, разнообразие подноса свежих продуктов, лоток и ланч-ланш-лан студентов быстрого питания в супермаркетах.

• HVT-A Series непрерывная вакуумная упаковочная машина

| √ | Высокоскоростной | √ | Заменяемая плесень |

| √ | Расширенное сохранение | √ | Высокая скорость замены газа |

| √ | Красивая упаковка |

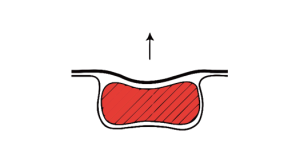

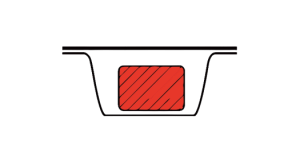

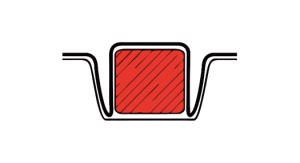

КАРТА |  Вакуумная упаковка |  Только герметизация |  Упаковка кожи (необязательно) |

Использование заменяемых форм, которые в большей степени соответствуют обновлениям пользовательского продукта, вы можете заменить упаковочные коробки с различными спецификациями в соответствии с потребностями в упаковке продукта. Полученная для упаковки коробки с различными требованиями (только герметизация; вакуумное уплотнение: модифицированная упаковка атмосферы;

Упаковка кожи (необязательно)).

| Сохранять свежую и повысить ценность

Он может продлить срок годности продуктов питания, эффективно увеличивая цикл продаж и уменьшая пищевые отходы. У упакованных продуктов наблюдается трехмерный трехмерный смысл, улучшение значения внешнего вида и оценки продукта, и потребители могут коснуться и проверять качество продукта. Хороший эффект защиты продукта, он может исправить продукт в нижней части коробки, эффективно предотвратить шоки, фрикция и шар |  |

| Высокая эффективность

Hualian HVT-A Series Speed: только герметизация 10-12 циклов/мин; Вакуум, газовый и герметизирующий 3-5 циклов/мин. Непрерывная автоматическая машина для автоматического лотка может выполнять автоматическую упаковку без перерыва, что подходит для потребностей производителей среднего размера, значительно повышая эффективность упаковки и снижение затрат на рабочую силу. |

| Вакуумная карта, высокая скорость замены газа

Первоначальный импортированный газовый миксер может быть выбран для обеспечения стабильной и точной подачи газа. Применяется метод замены вакуума, и скорость замены газа высока. Независимое закрытое пространство заменяет газ в упаковке, обеспечивая высокую скорость замены газа, а скорость замены газа составляет ≥99,5%. (Промывка газа необязательно) |  |

| Гарантия безопасности

Автоматическое герметизация имеет функцию отображения статуса и ошибок программы в реальном времени, что может в любое время понять статус работы оборудования, чтобы обеспечить нормальную работу оборудования. В то время как оборудование оснащено аварийным переключателем. В случае ненормальной ситуации, переключатель может быть нажат на прекращение всех рабочих программ, чтобы обеспечить безопасность оборудования и персонала. |

|  |  |

| Курица | Фрукты | Морепродукты |

|  |  |

| Мясо | Креветка | Овощ |

| Модель | HVT-450A | HVT-550A | HVT-650A |

| Напряжение (V/Гц) | 3PH AC 380/50 220/60 | ||

| Запечатывающая мощность (w) | 2000 | ||

| | 0.5-0.6 | ||

| Max.width of Roll Film (MM) | 450 | 550 | 650 |

| Max.Diameter of Roll Film (MM) | 300 | ||

| Емкость насоса (м3 /ч) | 63 | ||

| Емкость (время/мин) | Только герметизация 10-12 циклов/мин; вакуум, газовый и герметичный 3-5 циклов/мин | ||

| Промывочный газ | N2 или N2+CO2 | ||

| Охлаждающий тип | Водяной охлаждение | ||

| Размеры камеры (L × w) (мм) | 450 × (200-400) | 550 × (200-600) | 650 × (200-800) |

| Внешние размеры (L × w × h) (мм) | 2800 × 950 × 1620 | 2960 × 1050 × 1620 | 2960 × 1150 × 1620 |

| Чистый вес (кг) | Прибл. 670 | Прибл. 750 | Прибл. 850 |

Макет

Корпус 304 из нержавеющей стали, а материал пресс -формы - алюминиевый сплав

Если вы изменитесь на вакуумный насос 100, скорость будет быстрее. Текущая стандартная машина представляет собой насос 63, со скоростью от 2,5 до 3 раза в минуту

Водяное охлаждение не влияет на нормальную работу машины. Если вам нужно быстро изменить форму позже, вы можете использовать водяное охлаждение для ускорения охлаждения плесени, а затем изменить форму

Все наши двери заперты. Если вы хотите выполнить функцию остановки открытия двери, у нас есть в общей сложности 9 дверей, и каждая дверь будет настроена для дополнительного $50, и будут добавлены дополнительные аксессуары.

Да. Еще один цикл в минуту

Он может быть подключен к газому миксеру, и предоставляется интерфейс. Вакуумная машина может контролироваться, но цена дороже.

Да. Выходная машина для машины питается, чтобы отправить коробку на следующую взвешивающую электронную шкалу и машину для маркировки.

Hualian map tray sealing machine is applicable to sealing various PP or PE trays and, as a reliable map tray sealer machine, can automatically complete vacuuming, gas flushing, sealing and film cutting. It effectively prolongs product shelf life while keeping the contents fresh and protected.