Hualian impulse heat sealing machine, designed as a reliable plastic bag sealing machine, is suitable for PE or PP bags with a thickness of 0.12–0.32 mm. It can easily handle thick heavy bags, M-fold bags, and bags containing powder at the mouth. As an efficient heat sealing machine for plastic bags, it is widely used in heavy-duty packaging for pet food, milk powder, grains, rice, and plastic particles. With high efficiency, power-saving performance, and a small footprint, it is the ideal choice for small and medium-sized factories.

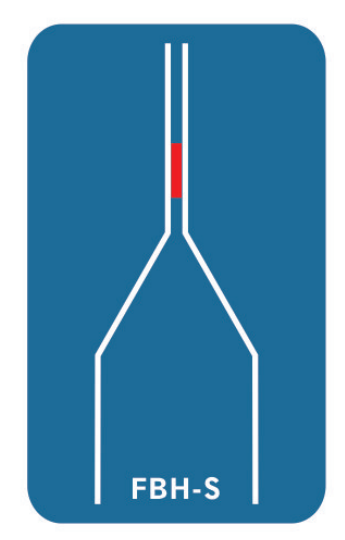

Máquina de sellado de calor de la serie FBH-S

| √ | Alta eficacia | √ | Salida alta |

| √ | Huella pequeña | √ | Interfaz de operación amigable |

| √ | Buen aspecto de sellado |

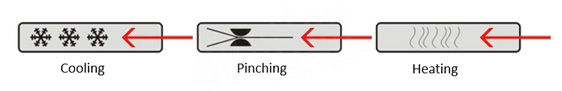

| • Modo de embalaje superior de la bolsa Es adecuado para la bolsa de educación física o pp con un grosor de 0.12-0.32 mm | • Selección de procedimiento de sellado Calefacción |

|  |

| Sellado de calor de alta eficiencia

As an advanced industrial plastic bag heat sealer, this impulse heat sealer works as a high-speed bag sealing machine, delivering up to 1800 bags/hour with PLC automation. The servo-driven sealing module returns quickly, reducing wait time and boosting sealing speed, while supporting pairing with an automatic bag placer machine as an efficient industrial bag sealer solution. |  |

| The sealing component uses a servo motor and ball screw mechanism for fast reciprocating motion, enabling quick return speeds, reduced waiting time, and significantly improved sealing efficiency. This makes it a reliable choice for users seeking a fast and stable plastic bag sealing machine. |

| Buena apariencia y conservación de energía

Esta máquina usa tela barnizada para separar la bolsa de envasado y el dispositivo de calefacción. Es fácil de enfriar después de calentar, tiene una superficie lisa, no es fácil de pegar y tiene una buena calidad de la superficie de sellado. Se adopta el control de la temperatura del pulso, que no requiere calentamiento continuo y es más eficiente en la energía. |  |

| Fácil operación y mantenimiento

Designed as a user-friendly industrial plastic bag sealer machine, it features a simple control interface, clear fault alarms, and convenient temperature adjustments. |

| Adopta el modo de sujeción de los cilindros delanteros y traseros para hacer que el sello sea seguro, y el módulo de sellado se puede mover para facilitar el mantenimiento. |  |

| Conectar con la línea de envasado El mecanismo de transmisión de la máquina adopta una cadena de sujeción especial, equipada con un convertidor de frecuencia para lograr la sincronización entre la entrada de la bolsa de empaque y la operación del transportador. Puede formar una línea de producción con el transportador, y puede formar una línea de producción de empaque completamente automática con medición automática, llenado automático, apilamiento, flejados de flecha y devanado. |

| Comodidad de la reparación posventa Excelente compra postventa sin preocupaciones |

|

|  |  |

| Industria química | Industria de fertilizantes compuestos | Industria de los plásticos técnicos |

|  |  |

| Industria de piensos | Industria de aditivos alimentarios | Médico Intermedio |

| Voltaje (V/Hz) | AC 380/50 3ph |

| Poder bruto (KW) | 5 |

| Velocidad de sellado (m/min) | 0-12 |

| Ancho de sello (mm) | 5 |

| Altura desde el centro de sellado hasta el piso (mm) | 800-1400 |

| La distancia mínima entre la parte superior de la bolsa (mm) | 180 |

| Rango de temperatura (℃) | 0-300 |

| Presión de fuente de gas (MPA) | 0.6 |

| Traje de movimiento del calentador | 550 |

| MAX.BAJO ANCHO (MM) | 460 |

| Espesor total de la bolsa (mm) | ≤0.8 |

| Material de bolsa | PE, polipropileno (PP) |

| Dimensiones (LXWXH) (mm) | 2500x1022x1800 |

Routine maintenance is recommended weekly to ensure consistent sealing quality. Click here for more details.

Yes. It supports continuous heavy-duty sealing for high-volume production. Click here for more Click here for more maintenance details.

Yes. It is compatible with M-fold and gusseted heavy bags.

No. It has a compact footprint suitable for small and medium factories.

Hualian map tray sealing machine is applicable to sealing various PP or PE trays and, as a reliable map tray sealer machine, can automatically complete vacuuming, gas flushing, sealing and film cutting. It effectively prolongs product shelf life while keeping the contents fresh and protected.