304 acero inoxidable

Pantalla táctil neinview

Omron plc

Sensor de marca de color de banner americano

Bomba Busch (opcional)

304 acero inoxidable

Pantalla táctil neinview

Omron plc

Sensor de marca de color de banner americano

Bomba Busch (opcional)

| √ | Estación dual giratoria |

| √ | Modo de control de vacío dual |

| √ | Se pueden combinar múltiples conjuntos de diferentes moldes de bandejas |

MAPA |  Empacación de aspiradora |  Solo sellado |  Embalaje de la piel (opcional) |

| Estación dual giratoria La eficiencia aumentó en 35%-45%, en comparación con la máquina de una sola estación

Se pueden combinar múltiples conjuntos de diferentes moldes de bandejas 5-10 minutos para reemplazar el molde |

| Vacú y deflación de doble modo Control de presión de liberación: Evite establecer el tiempo de deflación demasiado tiempo, puede causar desechos en la espera de acciones; Control de presión de vacío: Asegúrese de que el nivel de vacío dentro de cada bandeja pueda alcanzar el valor establecido. |  |

|  |

| 1. Modo de longitud fija Uso de un codificador rotativo para medir la longitud de la película que se alimentará, adecuada para películas en blanco | 2. Modo de seguimiento del código de color Uso del sensor de color para sentir la posición de las marcas de color en la película, adecuada para películas impresas con marcas de color |

|  |

| Sistema de desplazamiento al vacío sin conexión Alto grado de vacío, sin tubo de aire, sin fuga de aire | Cuchilla de corte de alto rendimiento Corte preciso y duradero |

|  |  |

| Pollo | Fruta | Mariscos |

|  |  |

| Carne | Camarón | Verdura |

| Modelo | HVT-370R | HVT-450R |

|---|---|---|

| Voltaje | 380V/50Hz (3ph) | |

| Presión de gas | 0.6 ~ 0.8MPA | |

| Capacidad de embalaje | Bomba de vacío estándar de 63m³/h, mapa: 2 ~ 3 veces/min | |

| Tasa de desplazamiento de gas | ≥99.5% | ≥99.5% |

| Max. Tamaño de la bandeja | 310 × 200 (2 bandejas/tiempo) 200 × 140 (4 bandejas/tiempo) (L × W) (mm) | 390 × 250 (2 bandejas/tiempo) 250 × 180 (4 bandejas/tiempo) 180 × 155 (6 bandejas/tiempo) (L × W) (mm) |

| Max. Altura de la bandeja | 80 mm 370 mm 300 mm 76 mm | 450 mm 370 mm 300 mm 76 mm |

| Dimensiones | 1280 × 1105 × 1540 (L × W × H) (mm) | 1380 × 1235 × 1540 (L × W × H) (mm) |

Disposición

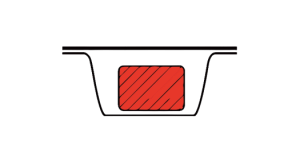

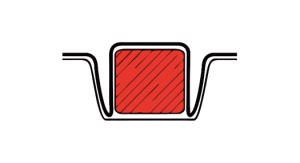

Un sellador de bandeja es un dispositivo de empaque que sella la película de plástico en bandejas de varios materiales, tamaños y profundidades. Se usa ampliamente para preservar la frescura y extender la vida útil de los productos alimenticios.

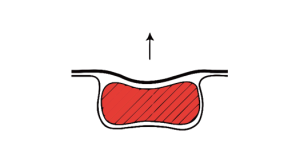

Después de que la bandeja se llena de productos, ingresa al sellador manualmente o mediante una cinta transportadora. Después de colocar la bandeja, la placa de sellado desciende, presionando la película a la bandeja, sellando la película a la bandeja calentando y cortando el exceso de película al mismo tiempo.

Solo sellado, sellado de vacío, mapa, paquete de piel.

MAP es una tecnología que puede preservar la carne, las frutas y las verduras sobre la base del almacenamiento de baja temperatura al cambiar artificialmente los componentes de los gases ambientales.

Cajas de embalaje: PP, PE, mascota, etc.

Películas de sellado térmico: PET/CPP, PET/PE, OPP/CPP, EVOH, papel de aluminio y películas compuestas que se pueden sarificar con el calor con las cajas de envasado correspondientes.

Al seleccionar un sellador de bandeja, se deben considerar factores como el tipo de producto, los requisitos de producción, el tamaño de la bandeja y el material para garantizar que el equipo satisfaga las necesidades específicas de la aplicación.

Limpie e inspeccione regularmente los componentes clave, como los elementos de calefacción y los moldes de sellado para garantizar el funcionamiento adecuado y la vida útil extendida del equipo.

La velocidad de producción depende del modelo y la aplicación específicos. Tenemos modelos manuales a automáticos, y diferentes modelos tienen diferentes velocidades.

Hualian map tray sealing machine is applicable to sealing various PP or PE trays and, as a reliable map tray sealer machine, can automatically complete vacuuming, gas flushing, sealing and film cutting. It effectively prolongs product shelf life while keeping the contents fresh and protected.