La máquina de envasado al vacío de bandeja continua de Hualian es aplicable a los tipos de sellado de bandeja de PP o PE, podría terminar el proceso de envasado al vacío, lavado de gas, sellado y corte de película, etc. Ampliamente utilizado en alimentos preparados, loncheras, comidas preparadas, etc. Puede prolongar el tiempo de vida de los productos manteniendo el producto fresco y previniendo los productos.

• Máquina de sellado de vacío de la bandeja de piel de la serie HVT

| √ | Alta eficacia | √ | Control inteligente |

| √ | Diseño compacto | √ | Moldes flexibles |

| √ | Monitoreo en tiempo real |

MAPA |  Empacación de aspiradora |  Solo sellado |  Embalaje de la piel (opcional) |

| Embalaje de bandeja de alta eficiencia

Alcanzar hasta 5-6 paquetes de mapas por minuto con una bomba de vacío de 360/V |  |

| Frescura duradera

Utilice un método de reemplazo de gas que minimice el consumo de gas mientras preserva efectivamente la frescura alimentaria durante un período más largo, extendiendo la vida útil y reduciendo los desechos.

|

| Operación Eazy y segura

Mantenimiento fácil: Equipado con pistas dedicadas, después de desbloquear el molde, se puede extraer directamente para un fácil desmontaje y mantenimiento. |  |

| En tiempo real: Se puede medir mediante medidor de presión digital y observación en tiempo real de los cambios de presión dentro del molde

Falla Función de inmediato en tiempo real: Instalado con un interruptor de emergencia, si hay alguna situación excepcional, el cliente puede presionar este interruptor para detener todo el programa de ejecución para garantizar la seguridad de la máquina y las personas. |

| Una máquina para múltiples propósitos

Moldes reemplazables adoptados para las actualizaciones de productos del cliente, se puede usar una máquina de ajuste |  |

| Construcción de alta calidad

Materiales de grado alimenticio: Los componentes principales están hechos de acero inoxidable o aleación de aluminio, que cumple con los estándares de higiene de alimentos y garantiza que el proceso de envasado sea seguro y confiable.

Estructura compacta: Ahorra espacio en el piso, es fácil de operar y es adecuado para diferentes entornos de trabajo. |

| Comodidad de la reparación posventa Excelente garantía de compra posventa sin preocupaciones es de un año. | |

|  |  |

| Pollo | Fruta | Mariscos |

|  |  |

| Carne | Camarón | Verdura |

| Modelo | HVT-350AZ |

| Voltaje (V/Hz) | 3ph AC 380/50 |

| Poder (KW) | 9kw |

| Relación de reemplazo de gas | Más de 99.5% |

| Altura máxima de la máquina estándar (mm) | 80 mm |

| Tamaño de la bandeja (mm) (L*w) | Máx.280*170 (4 bandejas/ciclo) min.180*100 (6 bandejas/ciclo) |

| Capacidad | 4-5 (empaquetado de mapas, con bomba de vacío 360m3/h) (ciclos/min) |

A sellador de bandeja is a packaging device that seals plastic film onto trays of various materials.sizes, and depths. lt is widely used to preserve the freshness and extend the shelf life offood products.

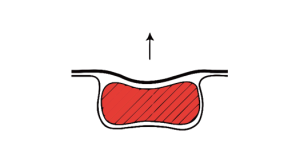

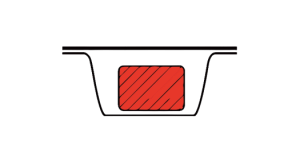

After the tray is filled with products, it enters the sealer manually or via a conveyor belt.After the tray is positioned, the sealing plate descends, pressing the film to the tray,sealing the film to the tray by heating, and cutting the excess film at the same time.

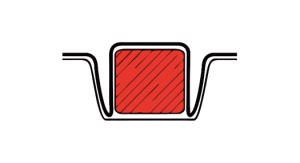

Solo sellado, sellado de vacío, mapa, paquete de piel.

MAP es una tecnología que puede preservar la carne, las frutas y las verduras sobre la base del almacenamiento de baja temperatura al cambiar artificialmente los componentes de los gases ambientales.

Packaging boxes: PP, PE, PET, etc.Heat-sealing films: PET/CPP, PET/PE, OPP/CPP, EVOH, aluminum foil and composite filmthat can be heat-sealed with corresponding packaging boxes.

Cuando selecting a tray sealer, factors such as product type, production requirements, traysize and material should be considered to ensure the equipment meets the specificapplication needs.

Regularly clean and inspect key components such as heating elements and sealing moldsto ensure proper operation and extended life of the equipment.

The production speed depends on the specific model and application. We have manuato automatic models, and different models have different speeds.

Hualian map tray sealing machine is applicable to sealing various PP or PE trays and, as a reliable map tray sealer machine, can automatically complete vacuuming, gas flushing, sealing and film cutting. It effectively prolongs product shelf life while keeping the contents fresh and protected.