Hualian map tray sealing machine is applicable to sealing various PP or PE trays and, as a reliable map tray sealer machine, can automatically complete vacuuming, gas flushing, sealing and film cutting. It effectively prolongs product shelf life while keeping the contents fresh and protected.

Hualian tray sealer, designed as an efficient map tray sealing machine, is applicable to sealing various PP or PE trays and can automatically complete vacuuming, gas flushing, sealing and film cutting. As a reliable map tray sealer machine, it helps prolong product shelf life while keeping the contents fresh and protected.

• HVT series semi-automatic tray vacuum sealing machine

| √ | 8 Times Fresher Lock | √ | Smart touch screen |

| √ | Multiple Functions Packaging | √ | Safety protection |

| √ | Food Grade Material |

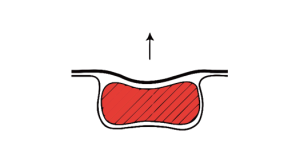

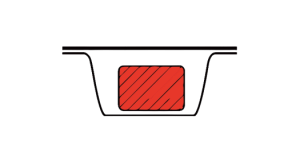

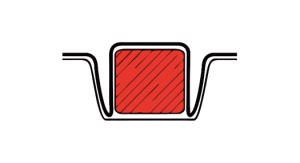

MAP |  Vacuum Packing |  Only Sealing |  Skin Packing(Optional) |

Packaging Types:Only sealing, vacuum sealing, gas-flushing packaging, skin packaging (optional)

| Lock In Freshness And Limit Shelf Life Of Food

Gas Flushing function: Helps lock in moisture for fruits and vegetables while reducing meat oxidation, delivering the preservation performance expected from a high-quality vacuum tray sealer machine.

High gas displacement rate: Gas replacement rate≥99.5%, this map packaging machine greatly extend the preservation time

|  |

| One Machine For Multiple Purposes The modular structure of this MAP tray sealing machine allows for interchangeable molds. Tray size, shape, and depth can be customized to meet your product specifications. |

| Safe and Secure Operation

Emergency stop switch: In case of emergency, it can be directly turned off for safety and security

Fault real-time prompt function: You can know the operation of the equipment at any time to ensure the normal operation of the equipment

|  |

| Food Grade Material

Food grade 304 stainless steel: anti-corrosion, easy to clean, durable and long-lasting.

Food grade aluminum mold: resistant to pressure and impact, ensuring food safety.

|

| Convenience Of After-sales Repair

Excellent after-sale purchase without worry Warranty is one year. Professional after-sale one -to-one Provide remote assistance services |

|  |  |

| Chicken | Fruit | Seafood |

|  |  |

| Meat | Shrimp | Vegetable |

| Model | HVT-450M/2 |

| Voltage (V/Hz) | AC 380/50(three phases) |

| Power (KW) | 3680 |

| Sealing power (KW) | 2000 |

| Ultimate vacuum pressure (KPa) | 1 |

| Flushing gas | N2 or N2+CO2 |

| Pump capacity (m3 /h) | 63 |

| Capacity (times/min) | 10-12 for only sealing ; 3-5 for vacuum, gas-flushing and sealing |

| Chamber Dimensions(L×W)(mm) | 400×(200-400) |

| Cooling type | Water-cooling |

| External Dimensions (L×W×H) (mm) | 1360×840×1475 |

| Net Weight (Kg) | Approx.650 |

Layout

The standard machine is 120mm, and it can be customized if it is larger than this size.

Yes,you needs to provide a matching film.

The mold needs to be provided to confirm that the new tray size is within the total size of the original tray vacuum chamber. If it exceeds the original size, there are too many parts to replace and no replacement is recommended.

The maximum diameter does not exceed 300 mm, and the maximum weight does not exceed 30Kg.

The machine itself has a tray ejection device, which only ejects 5-10 mm and then needs to be taken out manually.

Yes. MAP uses food-safe gases already present in the atmosphere and does not add chemicals. It is widely approved for global food packaging.

To understand the safety principles behind MAP, visit our educational article.