Hualian Automatic Sealing and Sewing Packaging Machine, designed as a durable bag sealing machine and heavy duty bag sealer, is suitable for packaging 20–50 kg heavy woven bags, PE composite bags, and similar large industrial packaging. This reliable industrial bag sealer offers stable performance for various bulk materials.

The Hualian Automatic Sealing and Sewing Packaging Machine, built as a powerful bag sealing machine and heavy duty bag sealer, is ideal for packaging 20–50 kg heavy woven bags, PE composite bags, and similar bulk materials—offering reliable industrial sealing performance to upgrade your production instantly.

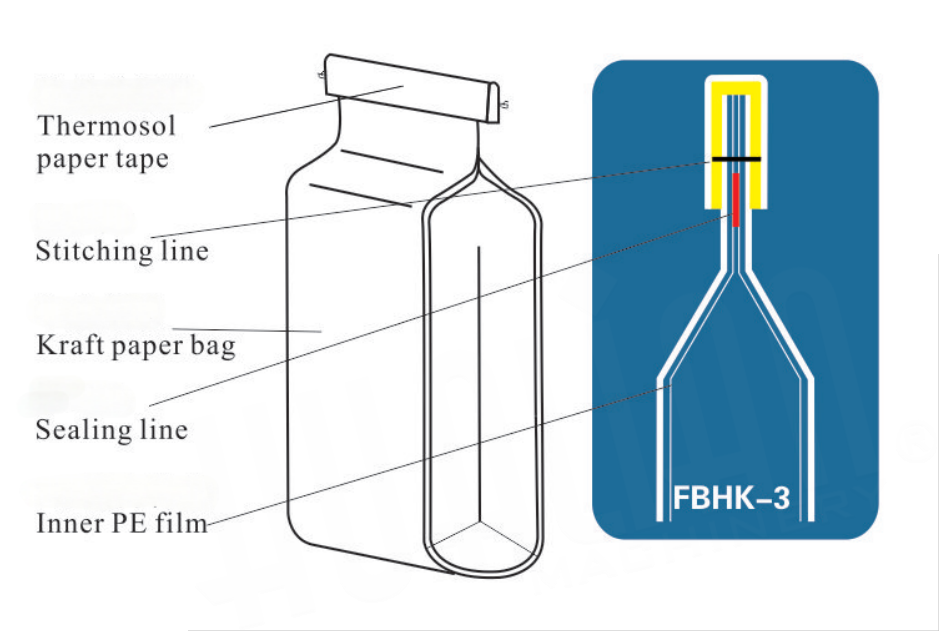

•FBHK-3 series Heavy-Duty Bag Sealing and Sewing Machine

| √ | High Efficiency | √ | Easy Operation |

| √ | Environmental | √ | Good Sealing Appearance |

| √ | Multi-function |

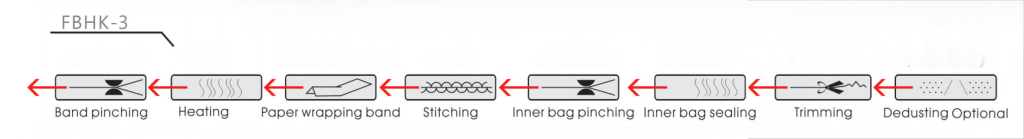

| •Mode Of Bag Top Packaging | •Sealing Procedure Sequence |

| First seal inner PE film, then stitch,and add thermosal paper tape for heating closure. | Dedusting Optional-Trimming-Inner bag sealing- Inner bag pinching-Stitching-Paper wrapping band-Heating-Band pinching |

|  |

| High-efficiency Packaging This heavy-duty bag sealing machine uses specially designed clip chain system ensures that the packaging bag and sewing machine run synchronously, effectively ensuring the accuracy and stability of the heating process and improving the overall packaging effect. And it use 75mm hot melt tape cover sewing needle holes,the sealing effect is firm and smooth. |  |

| Easy Operation and Maintenance The operation interface is simple, it’s easy to use without operator guidance. After turning on the switch, just set the appropriate heat sealing and heat sealing temperature. |

| Multi-function The heavy bag continuous sealing machine can be applied to various types of bags, such as woven (composite) bag/PP or PE bag/aluminum plastic composite bag with PE inner bag. It can automatically achieve dust removal (optional), heat sealing, sewing, pressing, trimming bag opening, wrapping with paper tape, sewing and other processes. |  |

| Energy Saving And Environmental Protection Heat sealing and stitching machine with a 0.75KW air pump dust removal, it removes bag openings dust efficiently. When it detects that the package has reached a specified position, it will start the dust removal mechanism to remove the dust at the bag mouth. It can effectively reduce energy consumption and waste rate during the packaging process, reduce pollution to the environment, and meet the environmental protection requirements of modern society. |

| Connect With Packaging Line The transmission mechanism of the sealing machine adopts a special clamping chain, equipped with a frequency converter to achieve synchronization between the input of the packaging bag and the operation of the conveyor. It can form a production line with the conveyor, and can form a fully automatic packaging production line with automatic metering, automatic filling, stacking, arrow strapping and winding processes. |  |

| Convenience Of After-sales Repair Excellent after-sale purchase without worry Warranty is one year. Professional after-sale one -to-one Provide remote assistance services

| |

|  |  |

| Chemical Industry | Compound Fertilizer Industry | Engineering Plastic Industry |

|  |  |

| Feed Industry | Food Additives Industry | Medical Intermediate |

| Model | FBHK-332C | FBHK-332DC |

| Voltage(V/Hz) | AC 380/50 | |

| Gross Power(KW) | 6.5 | 7 |

| Transmission Power(KW) | 0.75 | |

| Motor Power of Sewing Machine(KW) | 0.37 | |

| Heating Power(KW) | 0.5×10 | |

| Deduster Power(KW) | – | 0.75 |

| Sealing Speed(m/min) | 8.5(Customized upper limit 11) | |

| Height From Sealing Center to the Floor(mm) | 800-1400 | |

| Min.distance between the top of bag and the products (mm) | 180 | |

| Temperature Range(℃) | 0-300 | |

| Air Source Pressure(Mpa) | 0.6 | |

| Paper tape | 75mm Thermosal paper tape | |

| External Dimension(L×W×H)(mm) | 2900×950×1800 | |

| Net Weight (kg) | 700 | 750 |

It is suitable for 20–50 kg woven bags, kraft bags, and PE composite bags.

Yes. It performs sealing and stitching in one workflow to improve efficiency.

Yes. The sewing head can be adjusted to match various heavy bag materials.

The machine produces a secure, durable seal suitable for heavy-duty packaging.

Yes. The sewing head and moving parts need periodic lubrication for smooth operation. Click here to know more maintenance details.

Basic training is recommended to ensure safe operation and proper bag alignment.