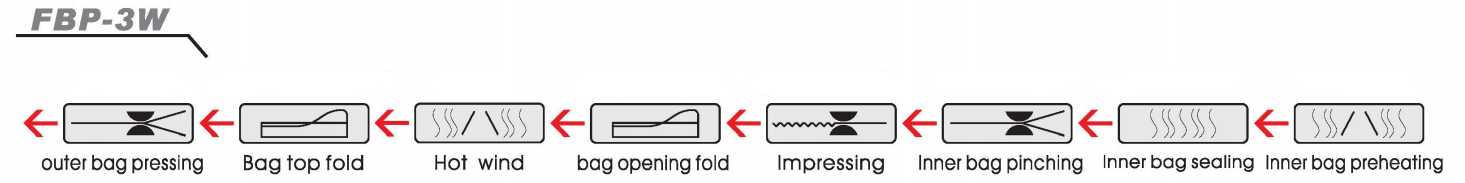

Hualian pinch bag sealer is suitable for sealing the flanging kraft paper bag,whose working process Is to fold the bag opening to 90 degree, heat bag top thermosol with hot wind, and then fold to 180 degree to pinch and seal.

• FBH-S series pinch bag sealing machine

| √ | High Efficiency | √ | High Output |

| √ | Small Footprint | √ | Multi-function |

| √ | Good Sealing Appearance |

| •Mode Of Bag Top Packaging | •Sealing Procedure Sequence |

|  |

| Multifunctional

Bag pinch sealer integrates folding, heating and pressing, and is suitable for various packaging needs of multi-layer tongue-mouth paper bags and liner bags. Whether it is preheating, heat sealing or folding of the outer bag, one machine can complete all processes, greatly improving production efficiency and reducing equipment investment costs. |  |

| Intelligent automation

It adopting advanced optomechanical integration technology, the machine can automatically complete complex processes such as bag opening, hot air preheating, heat sealing, and folding line indentation according to programming. When a fault occurs in each process, the machine will automatically alarm to ensure the stability and safety of the production process, reduce manual intervention, and reduce the difficulty of operation. |

| Precise temperature control and speed adjustment

The temperature of the hot air and heating block can be flexibly adjusted between 100°C and 350°C to meet the packaging needs of different materials. The transmission chain speed can also be adjusted between 6-12m/min to ensure that each process can be accurately controlled to meet the requirements of different production rhythms and improve packaging quality and consistency. |  |

| Excellent packaging effect

Through hot-press sealing technology, the packaging strength and sealing performance reach the best state, effectively preventing dust, moisture, mildew and pollution, ensuring that the packaging is fully protected. The packaged paper bags are neat and beautiful, which enhances the product image. They are especially suitable for sealing 20-25 kg paper-plastic composite bags to meet high-strength packaging needs. |

| Customized tear strip design

Hot-melt adhesive paper with tear strips can be customized according to customer needs to facilitate unpacking and enhance user experience. This design not only increases the practicality of the packaging, but also makes the packaging process more humane, especially suitable for scenarios that require frequent unpacking, such as food, chemical and other industries. | |

| Convenience of after-sales repair

Excellent after-sale purchase without worry | |

|  |  |

| Chemical Industry | Compound Fertilizer Industry | Engineering Plastic Industry |

|  |  |

| Feed Industry | Food Additives Industry | Medical Intermediate |

| Model | FBP-3W |

| Voltage (V/Hz) | AC 380/50 |

| Gross Power(KW) | 7.5 |

| Transmission power(KW) | 0.75 |

| Heating power(KW) | 6.45 |

| Speed (m/min) | 0-10 |

| Bag type | Paper tape or Plastic bag with inner PE film |

| Flanging position | Under the fold 10-15mm |

| Bag type | Paper bag plastic bag with inner PE film |

| Height From Sealing Center to the Floor | 800-1400 |

| Dimension (L×W×H)(mm) | 3500×950×1800 |

| Net weight (kg) | 350 |

Regular maintenance, operation training, optimization of packaging materials

Food industry: such as the packaging of grain products such as rice and flour.

Chemical industry: such as the packaging of fertilizers, plastic particles and other products.

Building materials industry: such as the packaging of building materials such as cement, sand and gravel.

Yes, our bag dust removal function is to achieve this function

Yes, it is generally recommended that customers configure a 5-meter belt conveyor

Generally NEWLONG

Yes, the motor model and function of the explosion-proof motor can be communicated

The FBK-23C bag sealing machine is a high-performance bag packaging solution designed for heavy-duty applications. It is specifically engineered for 25–50kg heavy bags, making it an ideal industrial bag sealer for demanding production environments.

This heavy duty sealer supports a wide range of bag types, including single or multi-layer paper bags, paper-PE composite bags, 2-in-1 and 3-in-1 bags, aluminum-PE liner bags, and PE bags—ensuring maximum flexibility for industrial packaging needs.