The Hualian double folding industrial heat sealing machine delivers clean, secure sealing for 20–25 kg paper-plastic bags. With double-folded edges and easy-tear hot-melt strips, it offers fast unpacking and a premium, professional finish.

Hualian’s double folding and heat sealing machine is designed for 20–25 kg paper-plastic composite bags, creating clean double-folded edges and applying customizable hot-melt easy-tear strips. It makes unpacking effortless while delivering neat, premium-looking packaging.

• FBC series double folding and sealing machine

| √ | High Efficiency | √ | High Output |

| √ | Small Footprint | √ | Multi-function |

| √ | Good Sealing Appearance |

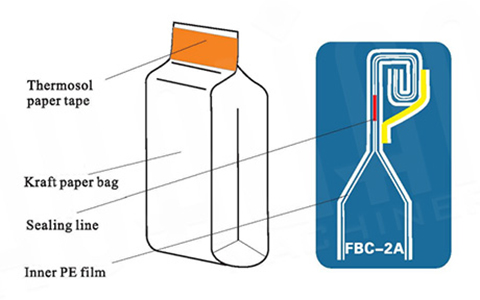

•Mode Of Bag Top Packaging

•Sealing Procedure Sequence

Dedusting-Inner bag Sealling-Inner bag Impressing-Trimming Impressing-First Folding-Second Folding-Tape Sticking-Tape Pinching

| Good Sealing Performance

This double folding automatic heat sealer adopts a controllable constant-heating device to press and seal the inner plastic layer, ensuring excellent sealing performance. It delivers dust-proof, moisture-proof, and contamination-resistant packaging that effectively protects your products. |  |

| Automated Operation

As a highly efficient double folding automatic bag sealing machine, it completes the entire packaging workflow automatically through a PLC-controlled program. The process includes dedusting, inner bag sealing, folding, tape application, and final sealing—ensuring a smooth, consistent, and fully automated packaging cycle. |

| Customizability

This double folding industrial heat sealing machine can be equipped with an optional dedusting system to clean the bag opening. It supports various bag formats, including monolayer bags, multilayer bags, kraft paper bags, and paper-plastic composite bags, offering strong adaptability for different packaging requirements.

|  |

| Versatile Integration

Can be easily integrated into a complete production line with additional equipment such as automatic weighing, filling, palletizing, strapping, and film wrapping, enhancing overall production efficiency. |

| Convenience Of After-sales Repair

Excellent after-sale purchase without worry | |

|  |  |

| Chemical Industry | Compound Fertilizer Industry | Engineering Plastic Industry |

|  |  |

| Feed Industry | Food Additives Industry | Medical Intermediate |

| Model | FBC-2 | FBC-2D |

| Voltage (V/Hz) | AC 380/50 | |

| Gross Power(KW) | 5.5 | 6 |

| Transmission Power(KW) | 0.75 | |

| Heating Power (KW) | 4.5 | |

| Deduster Power (KW) | – | 0.6 |

| Sealing Speed (m/min) | 0-11 | |

| Height From Sealing Center to the Floor (mm) | 750-1450 | |

| Temperature Range (℃) | 0-400 | |

| Air Source Pressure (Mpa) | 0.6 | |

| Deduster | × | √ |

| Specification of Hot Melt Tape (mm) | Width 70mm,paper core diameter 75mm | |

| External Dimension (L×W×H)(mm) | 3550×950×1800 | |

| Net Weight (kg) | 350 | |

Yes. It can connect with weighing, filling, palletizing, strapping, and film-wrapping equipment.

Yes. An optional dedusting mechanism is available to clean the bag opening before sealing.

It uses a constant-temperature heating device that pinches the inner plastic layer to create a tight, durable seal.

A one-year warranty, one-to-one technical guidance, and remote troubleshooting are included.

The FBK-23C bag sealing machine is a high-performance bag packaging solution designed for heavy-duty applications. It is specifically engineered for 25–50kg heavy bags, making it an ideal industrial bag sealer for demanding production environments.

This heavy duty sealer supports a wide range of bag types, including single or multi-layer paper bags, paper-PE composite bags, 2-in-1 and 3-in-1 bags, aluminum-PE liner bags, and PE bags—ensuring maximum flexibility for industrial packaging needs.